In the rapidly evolving world of manufacturing, staying ahead means embracing innovation. One such groundbreaking solution is Repmold. This advanced technology has been making waves across various industries, transforming how products are designed and produced. Imagine achieving superior quality while cutting down on costs and minimizing environmental impact. Sounds enticing, right? As we delve into the key benefits of using Repmold in modern production, you’ll discover why it’s becoming a game-changer for manufacturers looking to thrive in today’s competitive landscape. Let’s explore what makes Repmold an essential tool for progressive production methods!

Enhanced Product Quality and Consistency

Repmold plays a crucial role in enhancing product quality. Its precision molding technology ensures that every piece is crafted to exact specifications. This level of detail minimizes defects and inconsistencies, leading to higher standards in production.

Moreover, the materials used in Repmold processes contribute significantly to durability. Stronger products result from advanced formulations that withstand wear and tear over time. This not only elevates customer satisfaction but also fosters brand loyalty.

Consistency is another hallmark of Repmold manufacturing. With automated systems closely monitoring each stage, variations are drastically reduced. This means businesses can rely on uniformity across large batches without compromising quality.

In competitive markets, superior product quality sets companies apart. By integrating Repmold into their production lines, manufacturers position themselves for long-term success and consumer trust.

Increased Efficiency and Cost Savings

Repmold technology significantly boosts production efficiency. It streamlines processes, allowing for faster turnaround times. Manufacturers can produce more units in less time without sacrificing quality.

Cost savings are another compelling advantage of Repmold. By reducing waste and minimizing rework, companies can see a noticeable drop in operational costs. This translates to higher profit margins and better resource allocation.

Moreover, the precision offered by Repmold means fewer defects during manufacturing. Fewer defects lead to reduced material costs and lower labor expenses associated with corrections.

Investing in Repmold also enhances labor productivity. Workers spend less time troubleshooting issues and more time on value-added tasks. Consequently, businesses operate smoother while maximizing their workforce capabilities.

Adopting this innovative approach not only improves output but also strengthens competitive positioning within the market.

Sustainability and Environmental Impact

Repmold technology plays a significant role in promoting sustainability within modern production. By utilizing advanced materials and efficient processes, manufacturers can minimize waste significantly.

The precision of Repmold enables the creation of components that require less material without compromising quality. This reduction directly translates to lower resource consumption.

Moreover, many Repmold products are designed for longevity. Their durability leads to decreased frequency of replacements, which further supports environmental conservation efforts.

Even the recycling potential is enhanced with this technology. Components made through Repmold can often be repurposed or recycled more easily than traditional alternatives.

As industries move toward greener practices, integrating Repmold could help achieve ambitious sustainability goals while meeting market demands effectively.

Application in Various Industries

Repmold technology has found its footing across multiple industries, proving versatile and adaptable. In the automotive sector, it streamlines production processes while ensuring precision in component manufacturing.

The consumer electronics industry also benefits significantly. Repmold enhances the quality of intricate parts used in devices like smartphones and tablets. This leads to better durability and performance.

In addition, healthcare manufacturers use Repmold for producing medical devices that require high standards of safety and accuracy. The ability to mold complex shapes makes it invaluable here.

Moreover, packaging companies are embracing this technology for creating lightweight yet robust materials that meet sustainability goals without sacrificing quality.

From aerospace to furniture design, Repmold’s applications continue to expand as industries recognize its potential for innovation and efficiency.

Potential Challenges and How to Overcome Them

Adopting Repmold in production processes can come with its own set of challenges. One notable hurdle is the initial investment required for technology and training. This can deter businesses from making the switch.

However, companies can mitigate this by conducting thorough cost-benefit analyses. Understanding long-term savings alongside upfront costs makes a compelling case for transition.

Another challenge is resistance to change within the workforce. Employees may feel apprehensive about new methods disrupting established routines. Providing clear communication and ongoing support eases these fears.

Additionally, technical issues may arise during implementation. It’s crucial to establish a reliable troubleshooting protocol and have access to experienced technicians who understand Repmold intricacies.

Staying updated on advancements in Repmold technology ensures that businesses remain competitive. Continuous learning fosters an adaptable culture that embraces innovation rather than shying away from it.

Future of Repmold in Production Processes

The future of Repmold in production processes is promising. As technology evolves, manufacturers are increasingly adopting advanced techniques to enhance efficiency and quality.

Innovations in materials science could lead to new formulations that improve the durability and functionality of Repmold products. This opens doors for unique applications across various sectors.

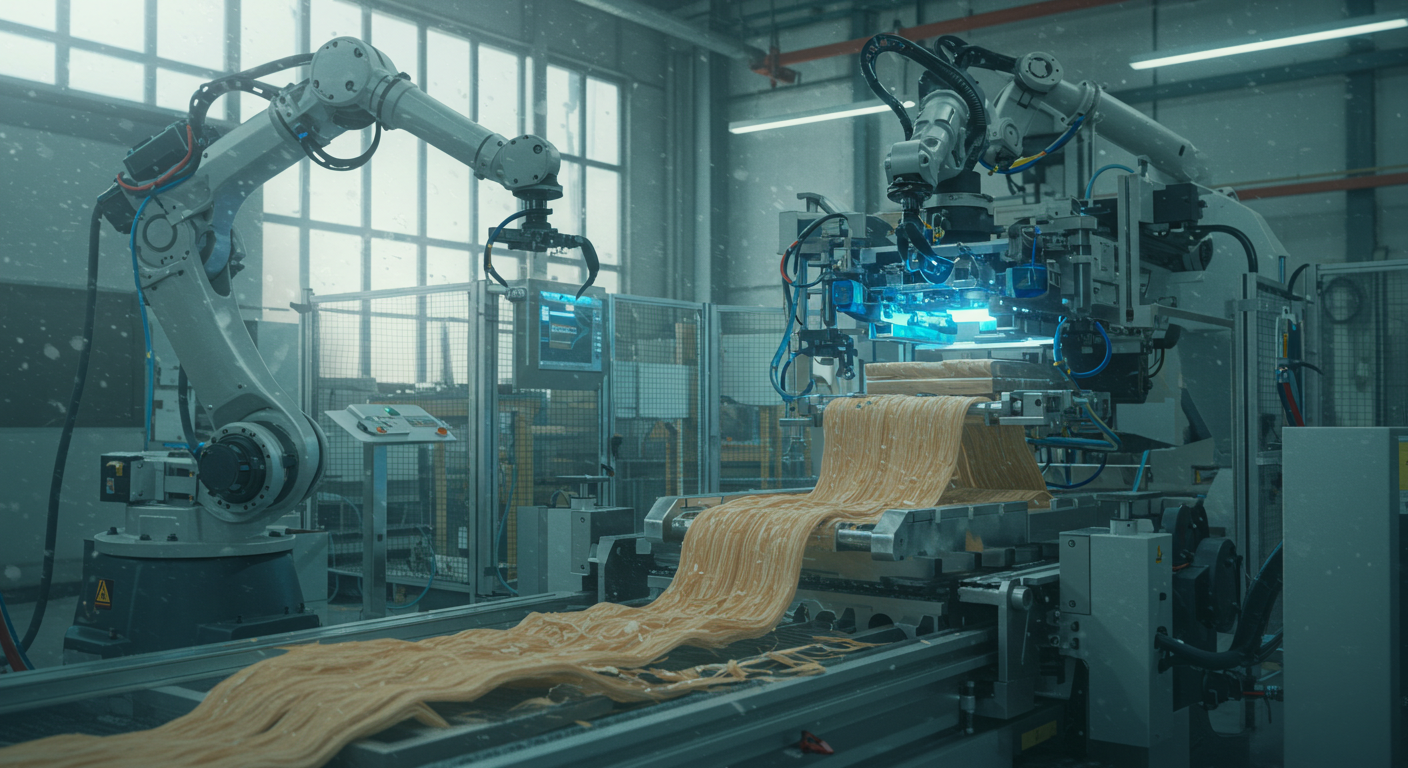

Automation also plays a crucial role. With robotics becoming more prevalent, integrating Repmold into automated systems can streamline operations further, reducing labor costs while maintaining precision.

Additionally, as sustainability becomes paramount, eco-friendly alternatives within the Repmold framework may emerge. These adaptations would not only meet regulatory demands but also cater to environmentally conscious consumers.

As industries continue to evolve, staying ahead with adaptive strategies will be essential for leveraging the full potential of Repmold technologies. Embracing these advancements ensures relevance in an ever-changing market landscape.

Conclusion

Repmold is transforming the landscape of modern production. Its ability to improve product quality and consistency stands out clearly. By employing advanced techniques, manufacturers can deliver reliable products that meet consumer expectations.

The boost in efficiency and cost savings cannot be overlooked either. Streamlined processes reduce waste and enhance output, making Repmold an attractive option for businesses looking to optimize their operations.

Sustainability also plays a vital role in today’s production environment. As industries shift towards greener practices, Repmold contributes by minimizing environmental impact through reduced material usage and waste generation.

The versatility of Repmold allows it to find applications across various sectors—from automotive to aerospace—demonstrating its adaptability. However, like any innovation, there are challenges associated with its implementation. Awareness of potential hurdles enables companies to devise effective strategies for overcoming them.

Looking ahead, the future appears bright for Repmold within production systems. As technology continues evolving, integration into new manufacturing methods will likely expand further.

Embracing this innovative approach could redefine how we think about production efficiency and sustainability moving forward.